Understanding The Importance Of Safety In Lathe Operations

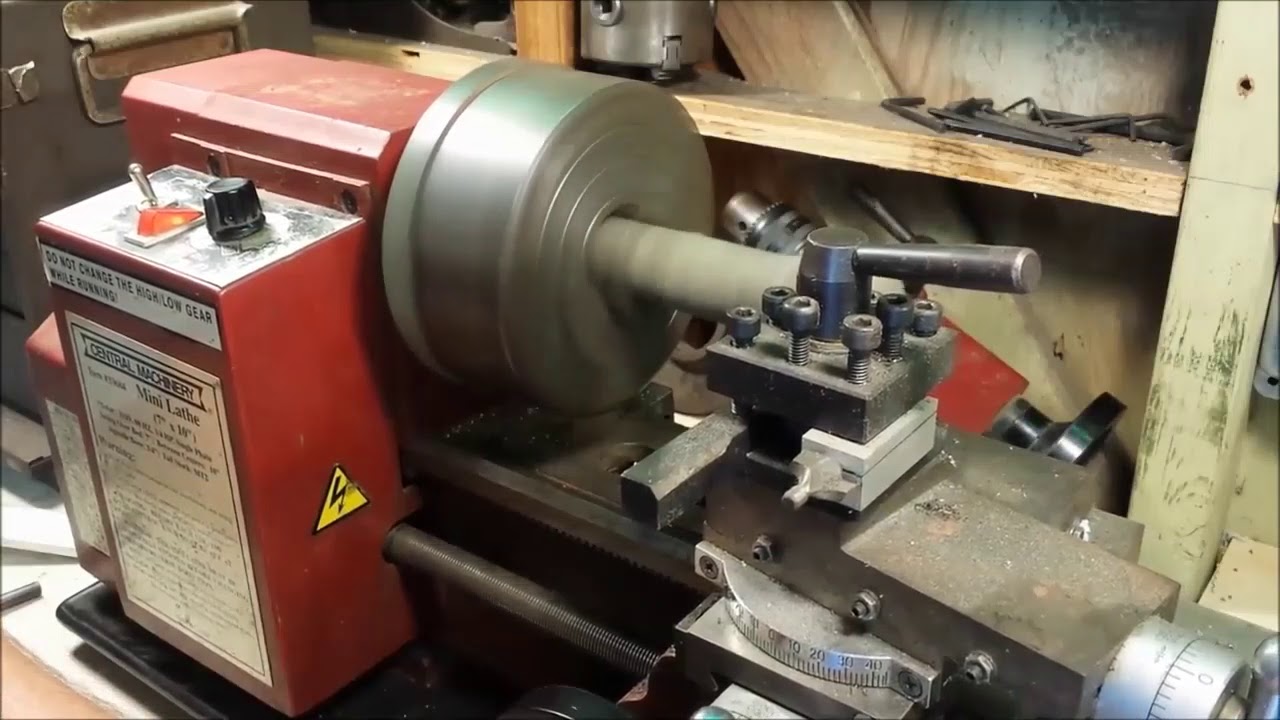

Lathe machines are versatile tools widely used in manufacturing and woodworking industries. However, they present significant risks when improperly handled. The growing number of lathe accident videos has drawn attention to the critical importance of safety measures in workshops and manufacturing environments. Although these videos often evoke distress, they serve as invaluable educational resources that underscore the dangers and consequences of neglecting safety protocols.

The unsettling nature of lathe accident videos evokes a wide range of emotions, from shock to a deep awareness of the hazards associated with operating such machinery. As these videos circulate on social media and professional forums, they spark discussions about the need for improved training, adherence to safety guidelines, and the significance of personal protective equipment (PPE). By analyzing these incidents, we gain a better understanding of what went wrong and how to prevent similar accidents in the future.

In this article, we delve into the various aspects surrounding lathe accident videos, including common causes of accidents, the importance of safety training, and the lessons we can learn from these unfortunate events. Our goal is to promote a culture of safety that prioritizes the well-being of everyone working with heavy machinery.

Read also:Anthony Howell Exploring The Life Love And Partnership Behind The Renowned Actor

Key Factors Contributing to Lathe Accidents

Lathe accidents typically arise from a combination of factors, which include:

- Inadequate operator training or experience.

- Non-compliance with established safety protocols.

- Improper use or lack of personal protective equipment (PPE).

- Mechanical failures or malfunctions within the lathe machine.

- Poor workspace organization leading to distractions or hazards.

How Effective Training Minimizes Lathe Accident Risks

Comprehensive training plays a pivotal role in reducing the likelihood of lathe accidents. Below are some key aspects of effective training:

- Thorough understanding of lathe machine operations and functions.

- Emphasis on safety protocols and the necessity of wearing PPE.

- Hands-on practice under the supervision of seasoned operators.

- Regular safety drills and refresher courses to reinforce knowledge.

The Role of Personal Protective Equipment in Accident Prevention

Personal protective equipment (PPE) serves as a crucial safeguard against injuries. Some essential PPE items include:

- Safety goggles to shield the eyes from flying debris.

- Ear protection to reduce noise exposure and prevent hearing damage.

- Gloves to protect hands from cuts, abrasions, and burns.

- Protective aprons to guard against hot metal shavings and hazardous liquids.

Are Lathe Accident Videos Valuable Educational Tools?

Despite their disturbing nature, lathe accident videos offer important educational value. They:

- Demonstrate the real-world consequences of safety lapses.

- Highlight the importance of adhering to safety protocols.

- Encourage meaningful discussions about safety in workshops and factories.

Steps to Take When Witnessing a Lathe Accident

Witnessing a lathe accident can be emotionally challenging. Here’s what you should do:

- Ensure your own safety before assisting others.

- Call for emergency medical assistance immediately.

- Provide first aid if you are trained and capable of doing so.

- Report the incident to the relevant authorities or supervisors.

Strategies for Enhancing Safety Culture in Workshops

To cultivate a strong safety culture, workshops can adopt the following strategies:

Read also:Exploring The Multifaceted World Of Chitra Sukhu Van Peebles

- Conduct regular safety training sessions and meetings.

- Establish clear safety protocols and ensure all employees are well-informed.

- Encourage open communication regarding safety concerns and suggestions.

- Invest in modern safety equipment and maintain machinery to prevent malfunctions.

Persistent Effects of Lathe Accidents on Victims

Victims of lathe accidents often face long-lasting consequences, including:

- Severe physical injuries requiring extensive rehabilitation and medical care.

- Emotional trauma and psychological impacts, such as post-traumatic stress disorder (PTSD).

- Financial hardships due to medical expenses and loss of income.

Who Are the Advocates Driving the Lathe Safety Movement?

The lathe safety movement involves various professionals committed to promoting safe practices, such as:

- Safety engineers who design and implement safety protocols.

- Regulatory bodies like OSHA (Occupational Safety and Health Administration) that enforce safety standards.

- Industry leaders advocating for enhanced training and improved safety standards.

Conclusion: Prioritizing Safety in Lathe Operations

Lathe accident videos serve as stark reminders of the dangers inherent in operating heavy machinery. By understanding the root causes of these accidents and promoting thorough safety training, we can significantly reduce the incidence of such tragedies. As we continue to learn from past mistakes, it is vital to cultivate a culture of safety that emphasizes the health and well-being of all workers. Let us commit to creating safer workplaces through education, awareness, and strict adherence to safety protocols.

Article Recommendations